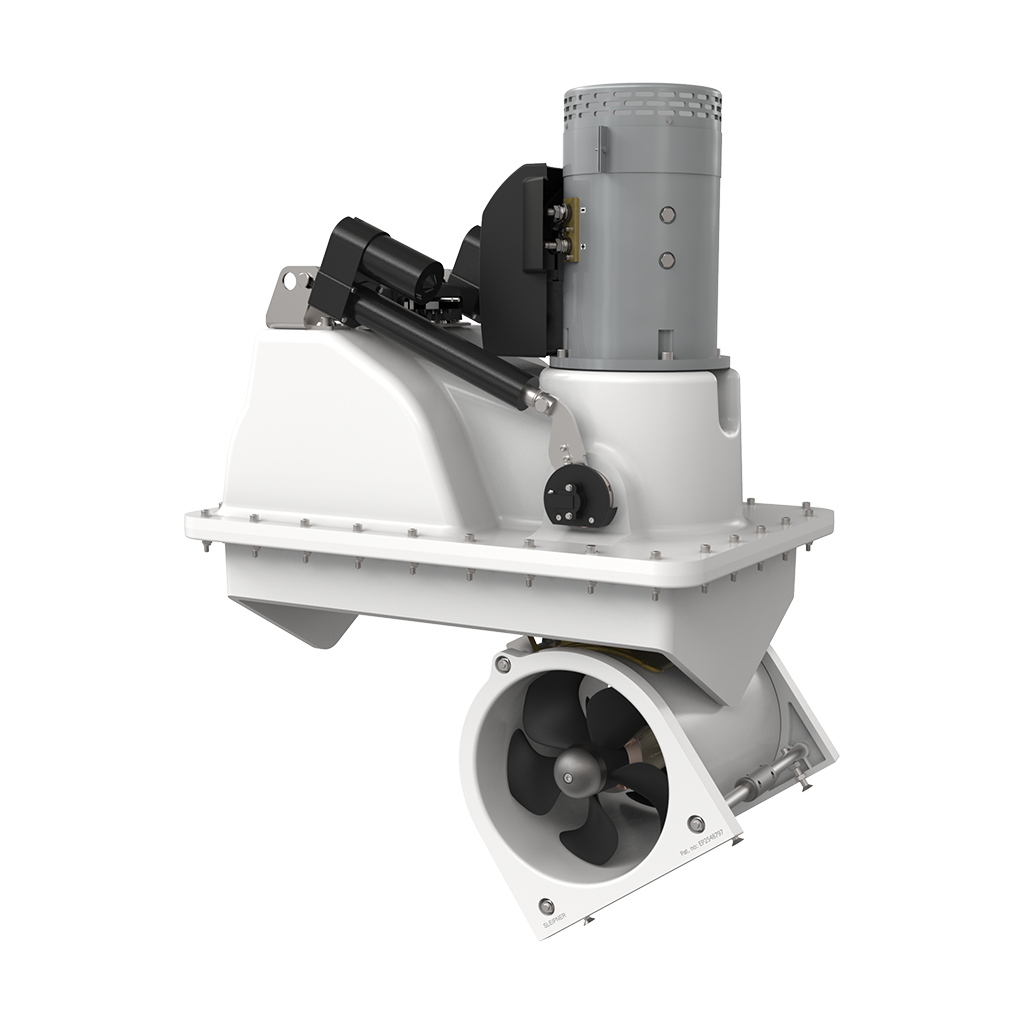

SRL100 Retractable thruster

100kg thrust on/off Low profil

The flange mounted SRL-series thrusters have the thruster unit in a casing that will be bolted to a base. This allows for easier installation in hulls made from different materials, as well as in series production where you do not need to mix laminating and engineering type jobs.

The 185mm tunnel diameter thrusters uses one fast and powerful actuator, while the 250mm tunnel diameter models have two actuators to handle the increased forces with the same exceptionally fast deploy/ retract operation time.

The unique design of the underwater mechanism with only a few, but very sturdy parts that all contribute to the stability of the moving assembly. The unit is also designed to keep the thruster as compact as possible while enabling the safe use of heavier motors on the more powerful units. The vertical installation of the motors also reduce the impact forces on the assembly in extreme waves compared to motors fitted at an angle.

The SRL100/185T thrusters are built with the same high safety standards as all Side-Power products, and incorporate all features introduced with the SE-series thrusters. Our focus on safety is a totally integral part of the product design so that everything from build quality to ease of installation is thought of to ensure long term reliability.

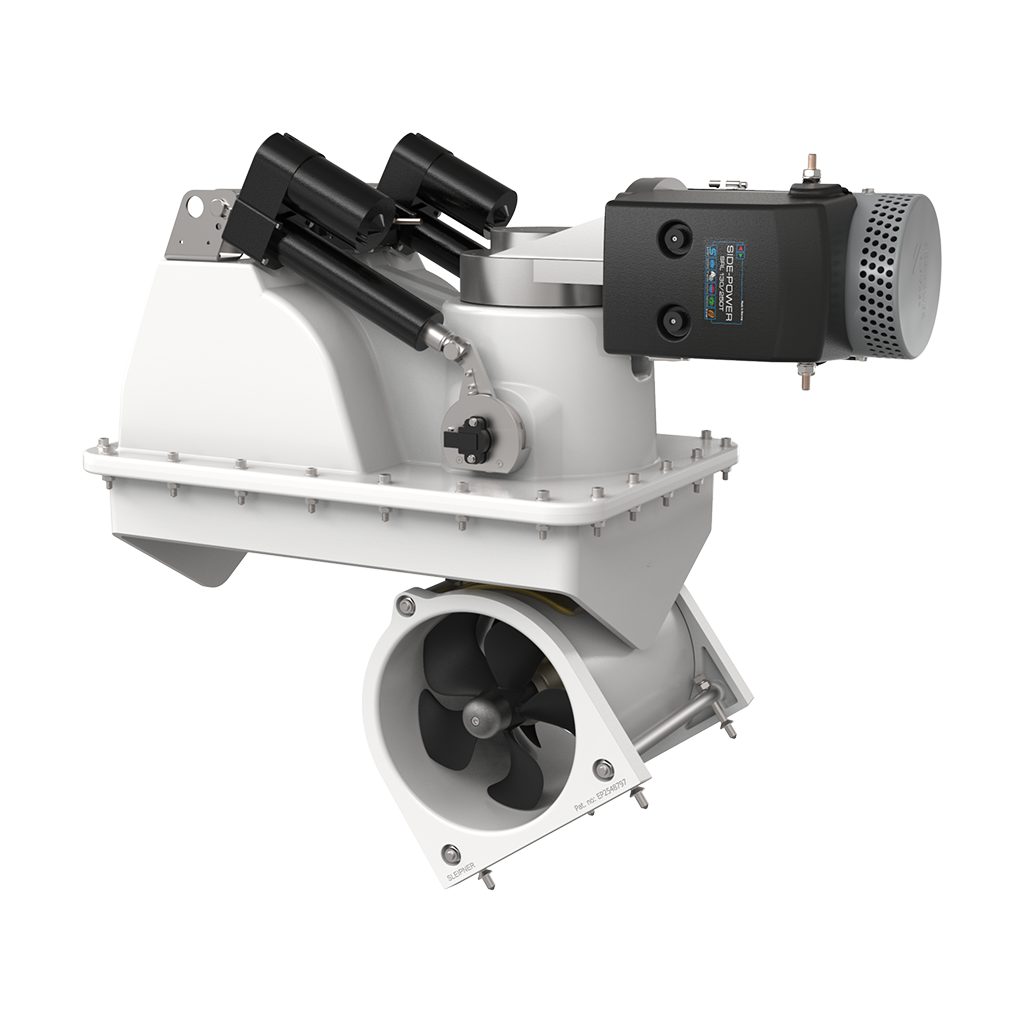

100kg thrust on/off Low profil

The flange mounted SRL-series thrusters have the thruster unit in a casing that will be bolted to a base. This allows for easier installation in hulls made from different materials, as well as in series production where you do not need to mix laminating and engineering type jobs.

The 185mm tunnel diameter thrusters uses one fast and powerful actuator, while the 250mm tunnel diameter models have two actuators to handle the increased forces with the same exceptionally fast deploy/ retract operation time.

The unique design of the underwater mechanism with only a few, but very sturdy parts that all contribute to the stability of the moving assembly. The unit is also designed to keep the thruster as compact as possible while enabling the safe use of heavier motors on the more powerful units. The vertical installation of the motors also reduce the impact forces on the assembly in extreme waves compared to motors fitted at an angle.

The SRL100/185T thrusters are built with the same high safety standards as all Side-Power products, and incorporate all features introduced with the SE-series thrusters. Our focus on safety is a totally integral part of the product design so that everything from build quality to ease of installation is thought of to ensure long term reliability.

100kg thrust on/off Low profil

The flange mounted SRL-series thrusters have the thruster unit in a casing that will be bolted to a base. This allows for easier installation in hulls made from different materials, as well as in series production where you do not need to mix laminating and engineering type jobs.

The 185mm tunnel diameter thrusters uses one fast and powerful actuator, while the 250mm tunnel diameter models have two actuators to handle the increased forces with the same exceptionally fast deploy/ retract operation time.

The unique design of the underwater mechanism with only a few, but very sturdy parts that all contribute to the stability of the moving assembly. The unit is also designed to keep the thruster as compact as possible while enabling the safe use of heavier motors on the more powerful units. The vertical installation of the motors also reduce the impact forces on the assembly in extreme waves compared to motors fitted at an angle.

The SRL100/185T thrusters are built with the same high safety standards as all Side-Power products, and incorporate all features introduced with the SE-series thrusters. Our focus on safety is a totally integral part of the product design so that everything from build quality to ease of installation is thought of to ensure long term reliability.

Intelligent Power Control

The Side Power unique thruster controller that intelligently protects the thruster from potential inherent problems in all high current applications as well as user faults. It includes several important safety features imperative in a product with such high power, run by DC electrics, as a thruster.

Provides delay between drive directions

Monitors solenoid functions to reduce the chance of solenoid lock-in

Will stop the thruster in case of a lockedin solenoid, without extra user action and even without controlling a main switch.

Q-prop™

The new 5 blade special skew propellers are the result of over 2 years of development work and thousands of tests. They have been designed to reduce the noise level, while maintaining the exceptional efficiency of the old 4 blade Side-Power propellers. This goal was achieved, and we even chose to make them a little bit more aggressive on some models, increasing the thrust on some thrusters about 5%. Please see individual information on each new thruster for more details.

Noise reductions of up to 75% measured in controlled environments

The expected and tested normal noise reduction in average installations: 20-40%

Will be delivered on all Side-Power models except models with 300mm and 385mm tunnel diameter

Upgrade kits are available for most SP series thrusters with special adaptors

Sealed and lifetime lubricated gearleg

Sealed gearleg with long-life "mechanical" seal where highly polished ceramic and carbon surfaces form the only moving sealing surfaces, ensuring protection against damaging water intrusion into the gear leg. Pre-filled with special gear oil for lifetime lubrication.

"Mechanical" seals with surfaces of ceramic and carbon for ultimate security against water intrusion

Twin Propellers

The twin propeller system can give more thrust than a single propeller system in the same tunnel diameter. This is our choice for our mid-range models where high thrust is required in a small tunnel diameter. Due to the compact design and high performance, the twin models have become the thrusters of choice among boat builders around the world.

Galvanic Separation

The gearhouse / drive legs of most Side-Power DC Electric thrusters are now fully galvanically isolated / separated from the electric motor and motor bracket. This ensures that even if there is an accidental short circuit or a current leak for other reasons, the immersed parts are not effected as they could be with direct electric contact.

Achieved by composite bushings around the bolts and beneath the washers and a bushing in the motor bracket electrically isolating the drive housing from the motor bracket.

Available on DC electric models with flexible couplers only, where the flexible coupler provides galvanic separation of the motor and gearleg shaft.

S-link™

S-link is a "CAN" based control system with full intelligent communication between all units in the system, much like a computer network.

Main advantages include:

Round, compact and waterproof connectors with unique keying and color coding to avoid faulty hookup

Unlimited number of commands or information transferred on a single cable

User feedback at panel

Intelligent troubleshooting